fume smoke extractor

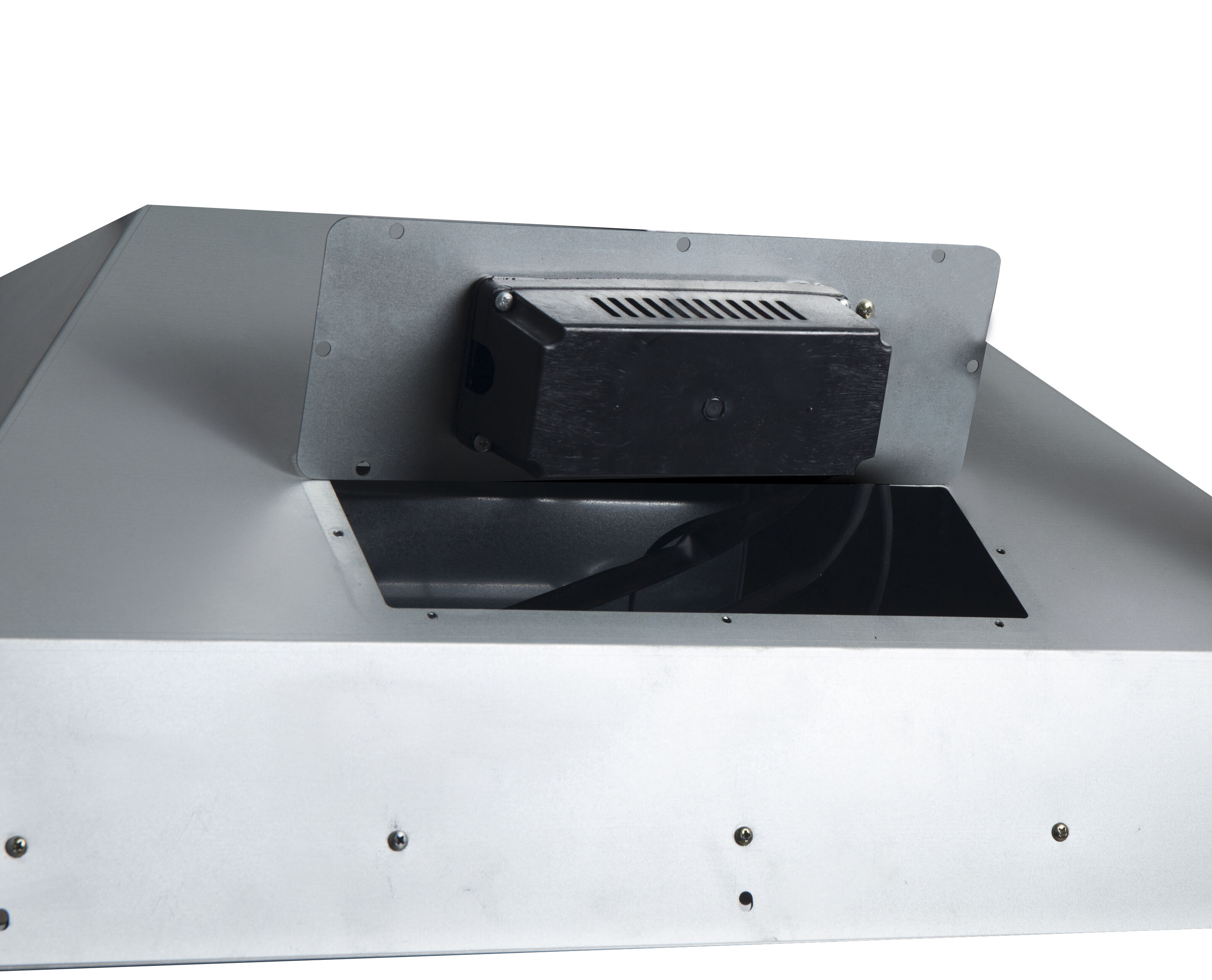

A fume smoke extractor is an essential piece of equipment designed to maintain air quality and safety in various work environments. This sophisticated system effectively captures and removes harmful fumes, particles, and airborne contaminants generated during industrial processes, welding, soldering, and chemical handling. The device utilizes advanced filtration technology, incorporating multiple stages of filtration including pre-filters, HEPA filters, and activated carbon filters to ensure comprehensive air purification. The extractor's powerful motor creates sufficient suction to capture contaminants at their source, preventing them from dispersing into the broader workspace. Modern fume extractors feature adjustable extraction arms that can be positioned precisely where needed, offering flexibility and optimal capture efficiency. Many units come equipped with digital controls for airflow adjustment, filter monitoring systems that alert users when maintenance is required, and energy-efficient operating modes. These systems are designed to meet strict occupational safety standards and environmental regulations, making them indispensable in industries ranging from manufacturing and automotive to electronics and laboratory settings.